CNC Aluminum Heating equipment series

We have been providing thermal solutions over 10 years for almost every industrial application field covering electronics, power generations, data centers, new energy, automobile, medical, chemical and construction machinery.

Some of the benefits of aluminum CNC machining include:

*High accuracy and repeatability

*Complex part geometries

*Lightweight and strong parts

*Corrosion resistance

*Low cost

- Sheungyin

- Foshan

- 15days

- 4000tons/month

- Information

- Video

- Download

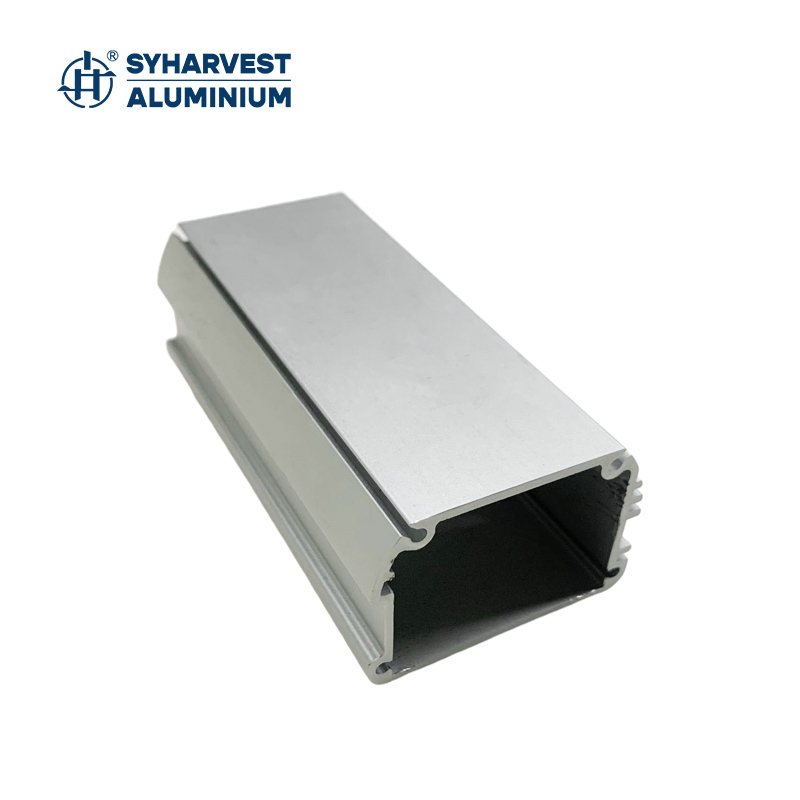

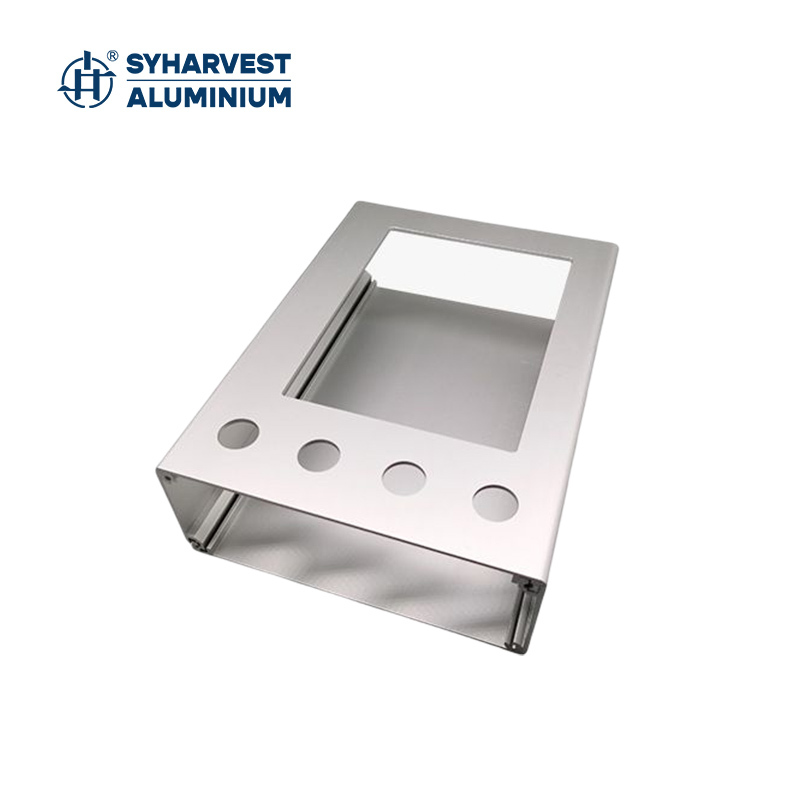

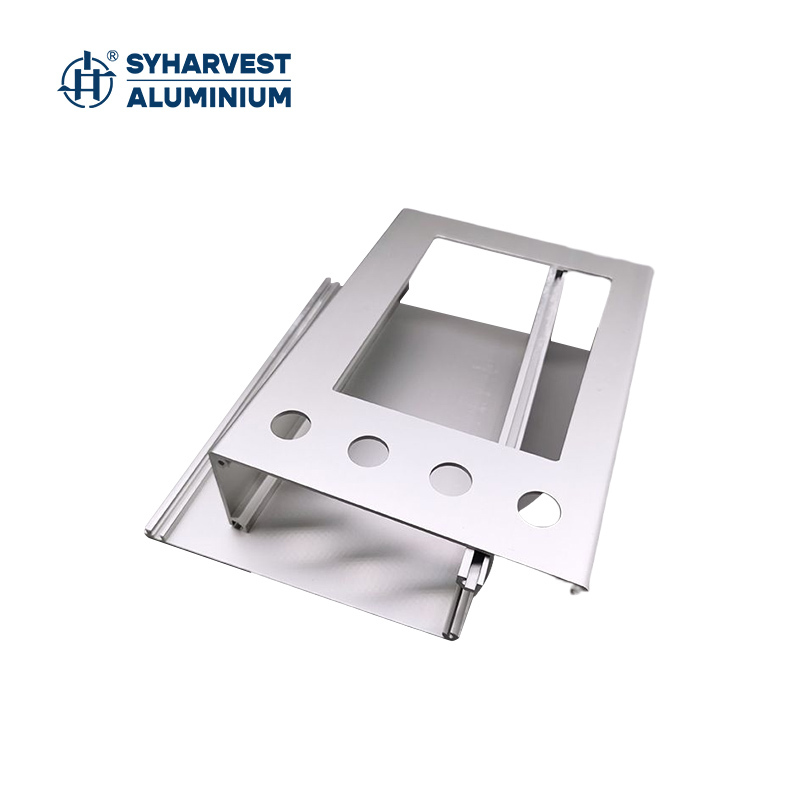

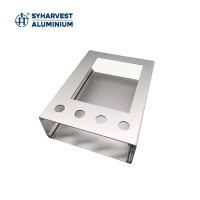

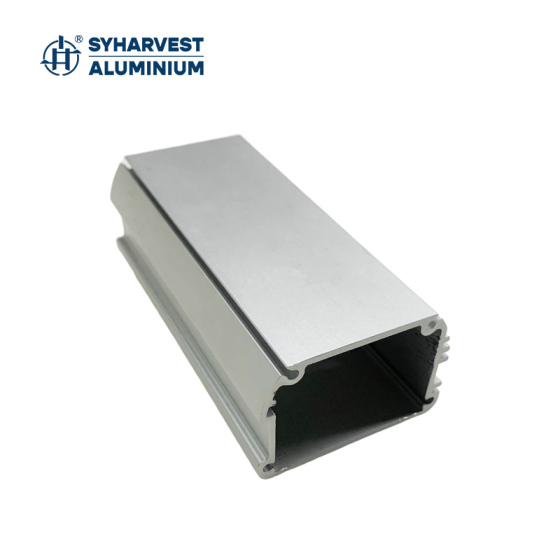

| Item Name | CNC Aluminum Heating equipment series |

| Origin | Foshan, China |

| Material | Aluminum AA6063 |

| Surface Treatment | Black Anodise/ Polish/ CNC Machining/ Extrusion |

| Packaging | Carboard box with wodden planks or as your required |

| Delivery Time | Within 12 working days |

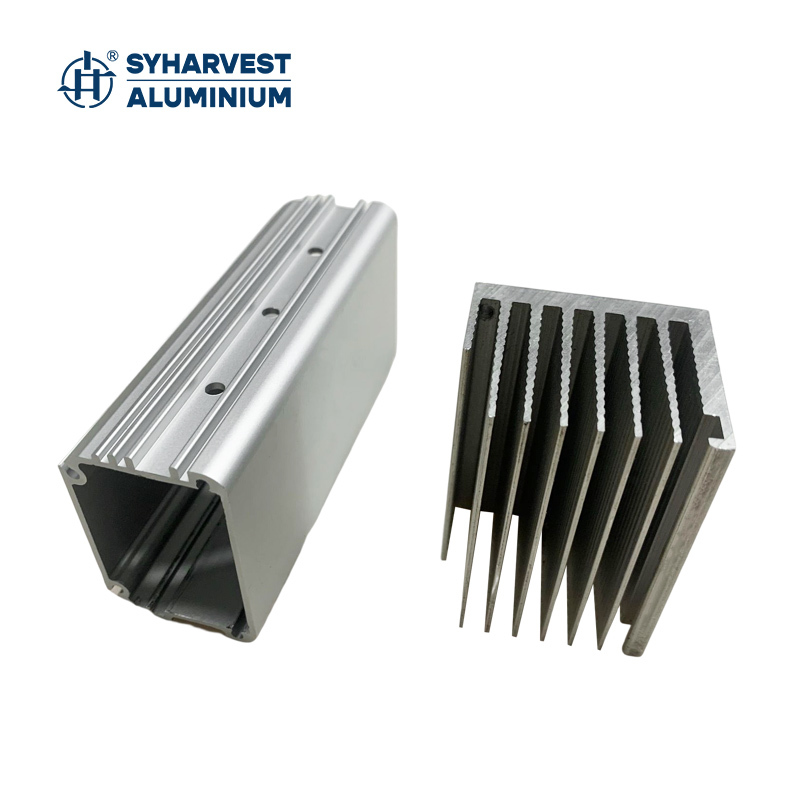

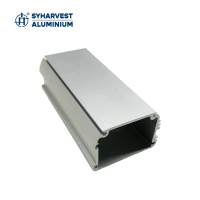

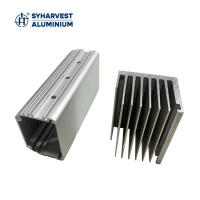

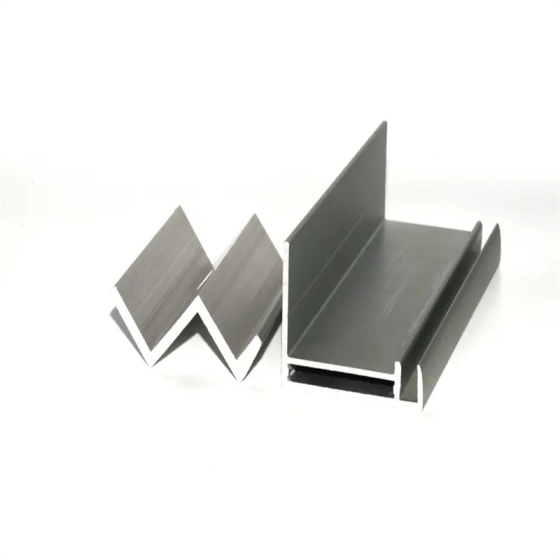

CNC aluminum heating equipment series is a type of heating equipment that uses CNC machines to create custom aluminum heat sinks. These heat sinks are often used in high-power applications where heat dissipation is critical, such as in power electronics, LED lighting, and industrial machinery.

The benefits of using CNC aluminum heat sinks include:

Increased heat dissipation efficiency: The complex geometries of CNC aluminum heat sinks allow for more efficient heat transfer than traditional heat sinks. This can lead to improved performance and reliability of the equipment in which they are used.

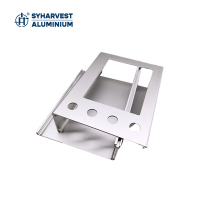

Increased durability: The high-quality aluminum alloy used in CNC aluminum heat sinks makes them very durable and resistant to corrosion. This can extend the lifespan of the heat sink and reduce the need for maintenance.

Customizable design: CNC aluminum heat sinks can be customized to meet the specific requirements of the application. This can be a valuable advantage in applications where space is limited or where the heat sink needs to be integrated with other components.

CNC aluminum heating equipment is a versatile and powerful tool that can be used in a wide variety of applications. The precision and efficiency of CNC machines make it possible to create custom heat sinks that meet the specific requirements of each application. This can lead to improved performance, reliability, and durability of the equipment in which they are used.