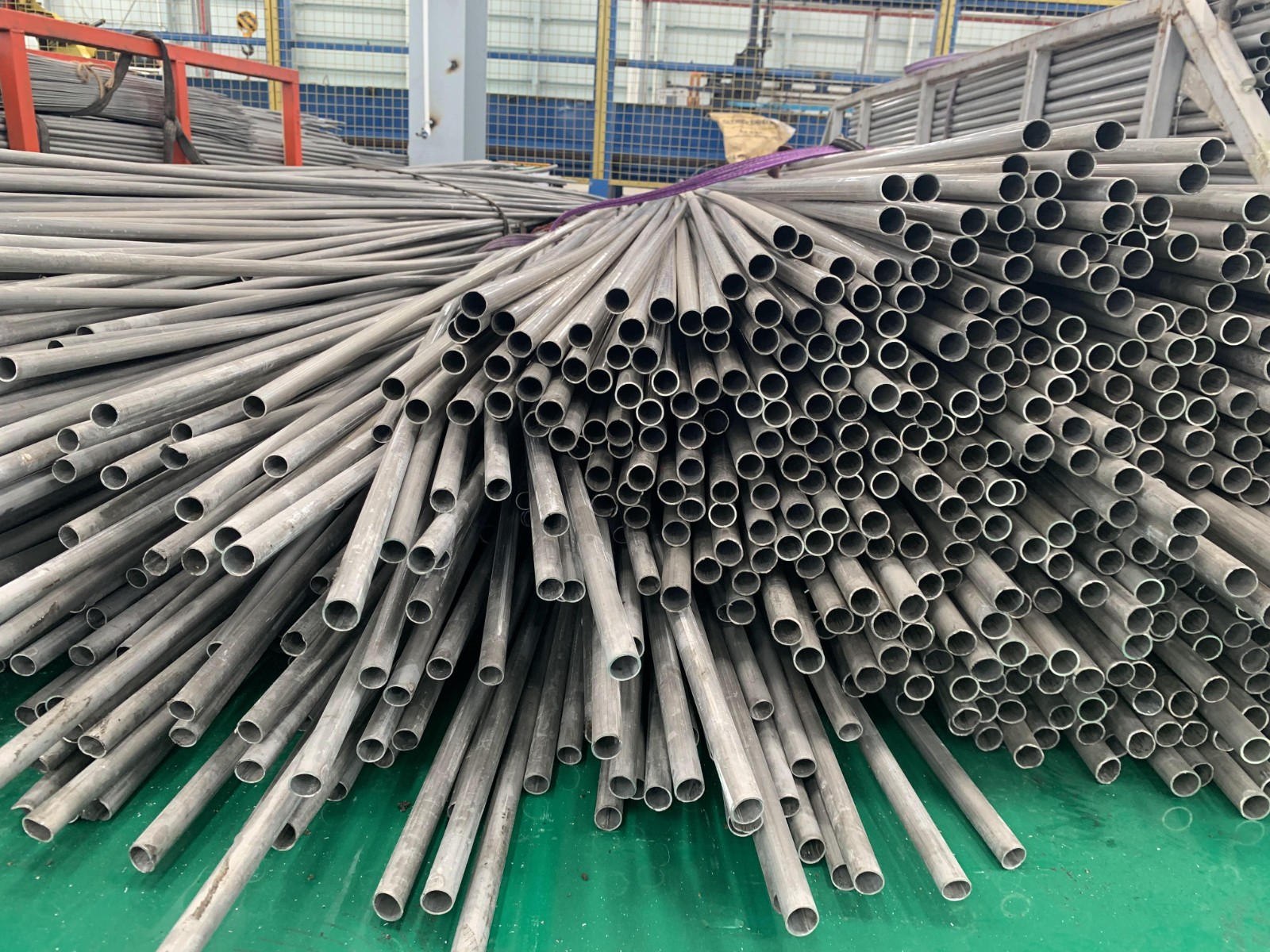

7075 Aluminium Alloy Seamless Tubes

Aluminum alloy seamless tubes are seamless tubes made of aluminum alloy material, with no welded joints on their inner and outer surfaces. They have advantages such as high strength, corrosion resistance, and lightweight. They are often used for transporting various high-pressure gases or liquids.

- Syharvest

- Foshan

- 15days

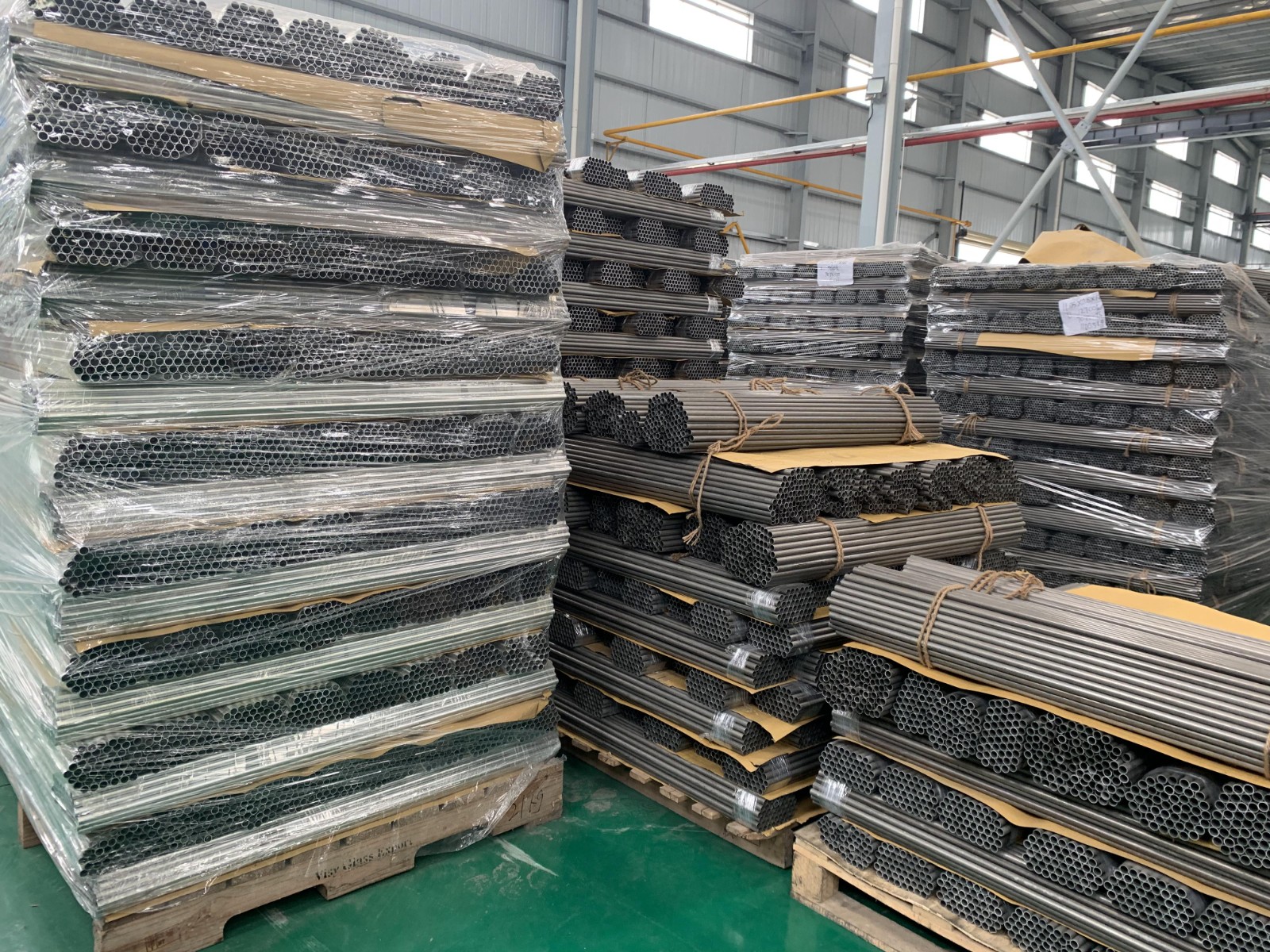

- 4000 Ton/Mouth

- Information

7075 Aluminum profile seamless tubes parts

Overview of Aluminum Alloy Seamless Tubes - Aluminum alloy seamless tubes are seamless tubes made of aluminum alloy material, with no welded joints on their inner and outer surfaces. They have advantages such as high strength, corrosion resistance, and lightweight. They are often used for transporting various high-pressure gases or liquids.

Overview of Aluminum Alloy Seamless Tubes - Aluminum alloy seamless tubes are seamless tubes made of aluminum alloy material, with no welded joints on their inner and outer surfaces. They have advantages such as high strength, corrosion resistance, and lightweight. They are often used for transporting various high-pressure gases or liquids.

We are aluminum factory and provide aluminum CNC machining service #heatsinks #heat #sink #heatsinksaluminum #enclosure #box #aluminumenclosure #aluminumheatsink #aluminumparts #aluminumextrusion #case #batterycase #extrusion #Anodized #CantonFair #Exhibition #parts

Delivery Time:8-14 days

Applications of Aluminum Alloy Seamless Tubes:

1. Aerospace Industry:

Aluminum alloy seamless tubes are commonly used in the aerospace industry for manufacturing oil and gas pipelines, hydraulic pipelines, and structural components of aircraft and rockets.

2. Chemical Industry:

In the chemical industry, aluminum alloy seamless tubes are often used as pipelines for transporting high-pressure gases or liquids, such as pipelines for oxygen production, nitrogen production, liquid oxygen, liquid nitrogen, and catalyst refining technology in the oil and coal chemical industries.

3. Machinery Industry:

Aluminum alloy seamless tubes are widely used in the machinery industry for high-pressure oil tubes, high-pressure steam tubes, high-pressure gas tubes, high-pressure water tubes, and more. Their high strength, corrosion resistance, and lightweight characteristics make them highly sought-after in the machinery industry.

Aluminum alloy seamless tubes possess the following characteristics:

1. Lightweight: Compared to traditional steel pipes, aluminum alloy seamless tubes are lighter, saving significant weight and reducing transportation and installation time and costs.

2. Corrosion Resistance: The surface of aluminum alloy seamless tubes is specially treated to effectively prevent chemical reactions and oxidation, providing strong corrosion resistance and prolonging their service life.

3. High Thermal Conductivity: Aluminum alloy seamless tubes exhibit excellent thermal conductivity, making them commonly used in the manufacturing of cooling systems and radiators.

The manufacturing process of aluminum alloy seamless tubes includes two main categories: hot rolling and cold drawing.

Hot rolling involves continuously heating aluminum ingots toAluminum a certain temperature and applying high pressure to transform them into tubular shape. Subsequent treatments and finishing are then performed to obtain aluminum alloy seamless tubes of specific sizes and shapes.

Cold drawing involves heating the aluminum alloy billet to a certain temperature and then subjecting it to seamless deformation through the process of drawing. The resulting tube undergoes further treatments such as wire brushing and nitriding to achieve the desired aluminum alloy seamless tube.